15/12 - AmbaFlex spirals twice as energy efficient

Since our inception, one of the focus points of AmbaFlex is to build the most energy-efficient machine possible. This focus is motivated by both a sustainability point of view as well as a more practical reason.

First and foremost, we want to be part of a sustainable future. As we share this goal with many major global players (e.a. Unilever: "Cut the environmental footprint of our products in half".), we continue to push onwards and decrease energy consumption even further.

Secondly, efficiency plays a big part in the wear and tear of a machine, and therefore in its total cost of ownership. The more energy a machine uses, the more stress it puts on its parts.

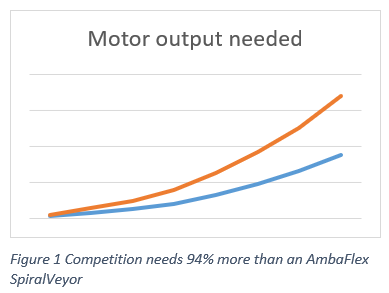

We often receive questions similar to "how can an extremely packed, wide belt SpiralVeyor handle its load with only a 6kw drive while some competitors* need 11kw or more". This was reason enough for us to start doing a number of head-to-head tests against our competition. We did this by building a direct copy of their machine, but with AmbaFlex technology, and put them through the same tests.

The results gave a very definitive answer to our customer's questions. Depending on the load, the competition required up to 94% more energy than the AmbaFlex spiral for the same result, which explains the significant difference in required drive capacity. The extra motor output or power our competitor needs, puts an immense amount of friction and stress on its parts.

AmbaFlex continuously refines and improves its technology. We launched our initial version of our Tripple-E technology back in 2005, the first low friction, guided roller system for spiral conveyors. Already a significant improvement to the standard in its own time, the continuous development shows its advantages in modern-day times are even more relevant. Cutting down on energy consumption and maintenance.

A decreased strain on our planet and increased performance for our customer, the best of both worlds.