4/1 - Transporting heavy loads in bulk

Efficiently transporting a large bulk of goods up or down is challenging in any circumstance. But, when space issues become part of the equation, it becomes even more difficult. This Indian end-user was, up until now, transporting all the goods manually and wanted to increase performance without redesigning a big part of the layout.

There are always multiple solutions to a problem. Most of them will do the job but choosing the one that fits your specific needs will give you the edge over your competition.

This solution needed to elevate a bulk flow of more than 20kg/meter; this means that platform or O-lifts were out of the question. In this scenario, the only real options were the incline belt and a spiral elevator due to their continuous flow and ability to handle large amounts of products with ease.

Both options have their own merits. But as the height difference they needed to overcome was 5+ meters, incline belts would've become too long to fit in the current design. Because available space was limited, and the engineers weren't too keen on redesigning the whole layout, only one option was left, a spiral conveyor. This option has the highest throughput and the smallest footprint of all possible solutions.

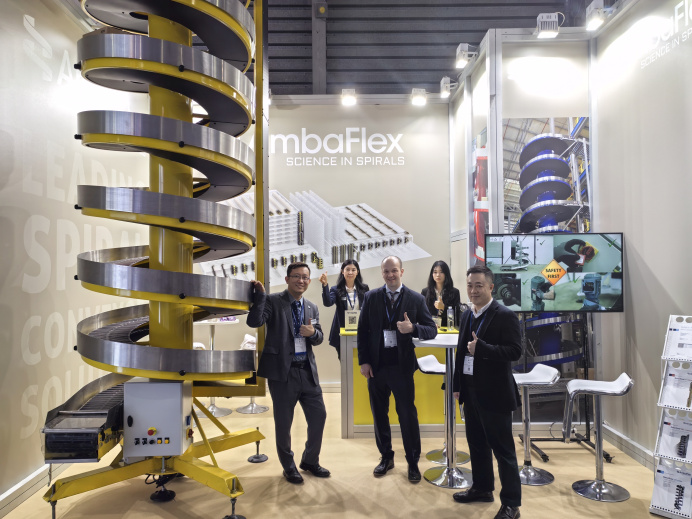

Our AmbaFlex SpiralVeyor SVe with a belt width of 1000mm was the perfect fit, capable of effortlessly elevating this massive flow of goods. All of this with a single track, a unique grip configuration to keep all of the products stable and in place, and a seamless 500mm stainless steel guide for safety. Besides the standard advantages of a spiral design, AmbaFlex products are incredibly reliable and easy to maintain. Keeping the line at optimum efficiency at all times.

AmbaFlex, elevating customers to greater heights!