12/6 - Coca-Cola Bottlers Japan

On May 29, Coca-Cola Bottlers Japan opened its Ebina Plant (Ebina City, Kanagawa Prefecture), where a new aseptic production line (new line No. 5) was introduced, to the media.

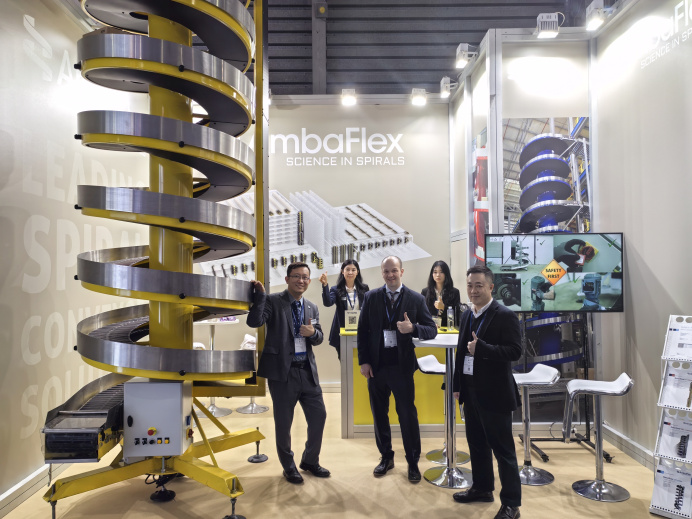

We are proud that AmbaFlex delivered 2 SpiralVeyor types SVm for Mass Flow handling and 1 SpiralVeyor SV for this plant! Key features are to save space in the plant and to handle the 900 bpm for products ranging in size from 190 ml to 500 ml. The high throughput speed can thus be guaranteed!

read the japanese case here; https://www.ryutsuu.biz/strategy/p053171.html

Atsuyuki Hatogai, Plant Manager of the Tama/Ebina Plant, SCM Division, who also serves as Plant Manager of both the Ebina and Tama plants, commented on the features of the new line, "The latest technology in the beverage industry is that the evolution of aseptics has made it possible to sterilize milk powder by adding it to the line at the same time. The production capacity of this line is 900 bottles per minute, but since it is technically difficult to find a machine such as a labeler, which requires precision, that can exceed 900 bpm, two 450 bpm labelers are used for labeling in two separate steps," he explained. Regarding his enthusiasm for the future, he said, "All beverage manufacturers have been restrained from developing new products due to the Corona disaster, but development will accelerate in the future. We would like to firmly establish our production and production line systems to respond to this trend, so that we can offer new products.

Outline of New Line No. 5

Name: Coca-Cola Bottlers Japan Ebina Plant No. 5

Production line: Aseptic line

Start of operation: April 2023

Production capacity: 900 bottles per minute (small PET bottle products)

Products manufactured: Small PET bottle products (tea, coffee, etc.)

The old No. 5 line at the Ebina Plant manufactured canned coffee and other products, but the new line was introduced to expand production capacity for small PET bottle products, for which demand is increasing. This has increased the number of items requiring aseptic filling and transportation efficiency throughout the company. The supply of canned coffee products, which had been manufactured until now, will be covered by the production at other plants.