18/12 - High-level Spiralling

Designing a production layout is often a puzzle where each choice for specific equipment and machines has both advantages and disadvantages. Getting the perfect mix for a given situation requires a lot of creativity. In this case, it was about keeping a high enough throughput and getting products elevated to the proper height while using only a small amount of floor space.

Project details

- Winning back floor space with a compact spiral

- High throughput for high-level palletizer

- Added protection against dirt and debris

- Easy and safe transfer thanks to transfer rollers

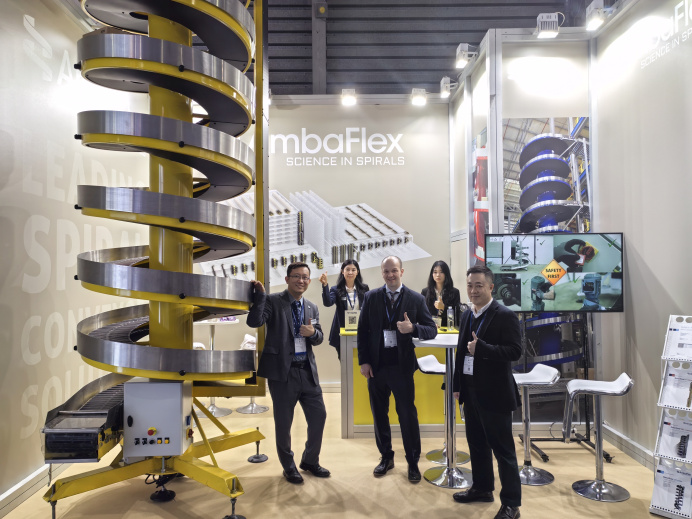

One of our customers, handling big bags of durum wheat, has a production line equipped with a high-level palletizer for maximum throughput and minimal handling of the bags to prevent any possible damage. The drawback was that they needed a way to get the products high enough for the infeed. Initially, the palletizer was connected through a regular incline conveyor. This increased the total floor space needed just to get all the bags ready for transport.

The customer needed to win back that precious space without sacrificing throughput or product safety. Our SpiralVeyor SV was an ideal fit. The continuous flow coupled with a compact footprint brought back the excess space and opened it up for a better and more efficient layout.

With additional features such as a dirt funnel in the return channel and an offset of the seamless B-guide, any debris and dirt are efficiently removed, keeping the whole journey upward clean as a whistle. Together with the transfer rollers for an extra compact and safe transfer on and off the spiral conveyor, this SpiralVeyor checked all the right boxes for this customer.

AmbaFlex, elevating customers to greater heights!