27/2 - CSL cuts to the chase with STIHL

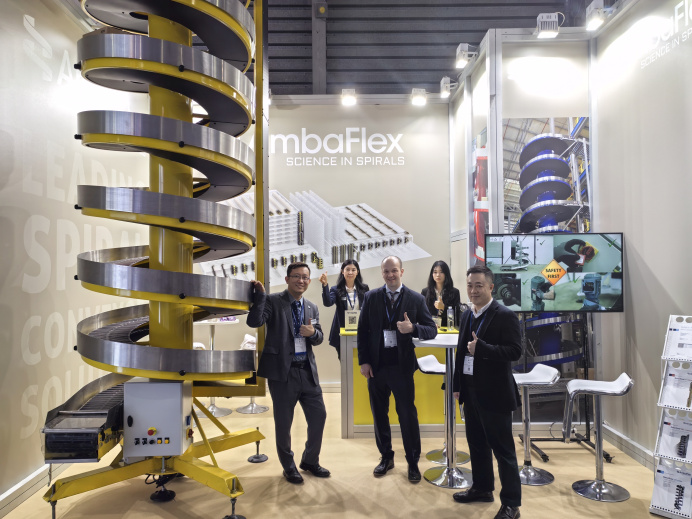

World Leading Chainsaw / Power tool brand –STIHL, appointed Conveyor Systems Ltd (CSL) to streamline their order picking operation, which is carried out over a two-tier mezzanine floor area. CSL, who recently celebrated their 100th AmbaFlex SpiralVeyor order, worked together with AmbaFlex to create a unique and efficient solution whilst saving valuable space.

STIHL approached CSL with a brief to provide a semi-automated system to accommodate order picking and stock replenishment over two floors, requiring a fully reversible solution. The solution required the ability to stop products between floors for consolidation. The challenge was to deliver a system that was both space efficient and featured a bolt-on approach for future integration to the new WMS, which would include barcode reading, to move to a fully automated system.

Previously STIHL, whose head-office for Great Britain is located in Surrey, conducted the process manually using pallet gates in conjunction with a fork lift truck to deliver palletized picked goods to the ground floor. The process was then done in reverse to replenish stock to the relevant floors.

To automate this process engineers stacked two SpiralVeyors on top of each other, creating a multilevel application, where products could be stopped at any level and the direction reversed when needed. Essentially operating as one solution, providing an infeed and outfeed from the first floor and delivering to either the ground or the second floor using the same common conveyors.

From the second floor, the totes are loaded onto a conveyor and conveyed down the first floor via the top spiral lowerator. Upon landing on the second floor, a manual sort determines whether the tote requires removal for order consolidation or placing onto the next conveyor to take to the ground. The second of the stacked spiral lowerators takes the product to ground, whereby another manual sort takes place. All finished orders are presented to a transit conveyor, which conveys the totes to end of line packing operation. Stock replenishment operates in reverse.

One more proof of AmbaFlex’s leading position in Spiral Conveyor Solutions!